How To Layout Metal Stud Framing

Glue or screw on the metal panels onto the other 3 faces of the frame.

How to layout metal stud framing. Cut the metal studs and tracks Cut both side flanges of a steel stud using straight-cut aviation snips. To do this youll need to leave that last stud loose until the drywall goes up. In addition to speeding up the framing process CFS panels contain pre-punched holes designed to.

Basic steel stud cutting tips and metal stud framing details Photo 1. Wherever a rafter bears onto a wall youll need a stud directly underneath. Apply a mark of metalworking glue across the metal plate posts on one face of the box press a plate panel onto the front side and then add it with screws.

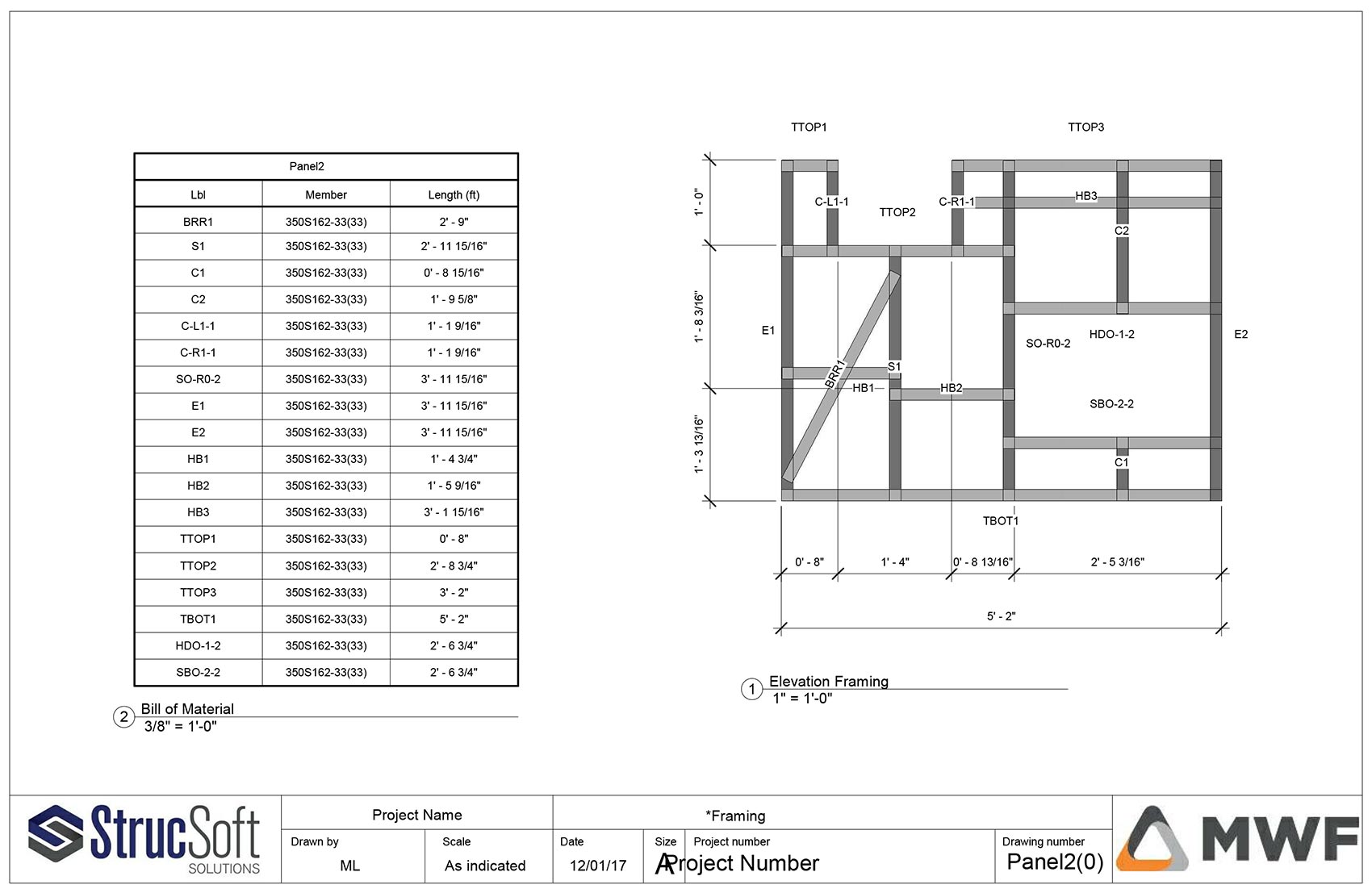

You should typically allow for 1 stud per every 12 inches 300 mm of linear wall space. The stud layout is marked on the platesthe horizontal members at the top and bottom of a wall. Today I am going to be talking about metal stud and drywall layout from the drawings.

Purchase steel plates also called tracks for the bottom and top of the wall by measuring the linear feet of the wall and doubling it. First the installer will measure the U studs to specifications of the floor plan making sure that each stud is exact in order to fit the layout. One of the easiest ways to keep a good layout is to just copy the trussjoistsrafters from up above.

The blueprints will rarely if ever specify the location of every stud so the carpenter is expected to understand framing principles. Add an additional stud for each side of a window or door. Then bend one flange up-clear of the snips jaws-and cut across the studs web.

Its worth taking the time to find straight long stock for the plates and to cut them accurately to length. Where hips girders and other heavy duty trusses land youll need to double or even triple up the studs to accept the load. One poorly measured stud can ruin an entire lay out making it harder to.