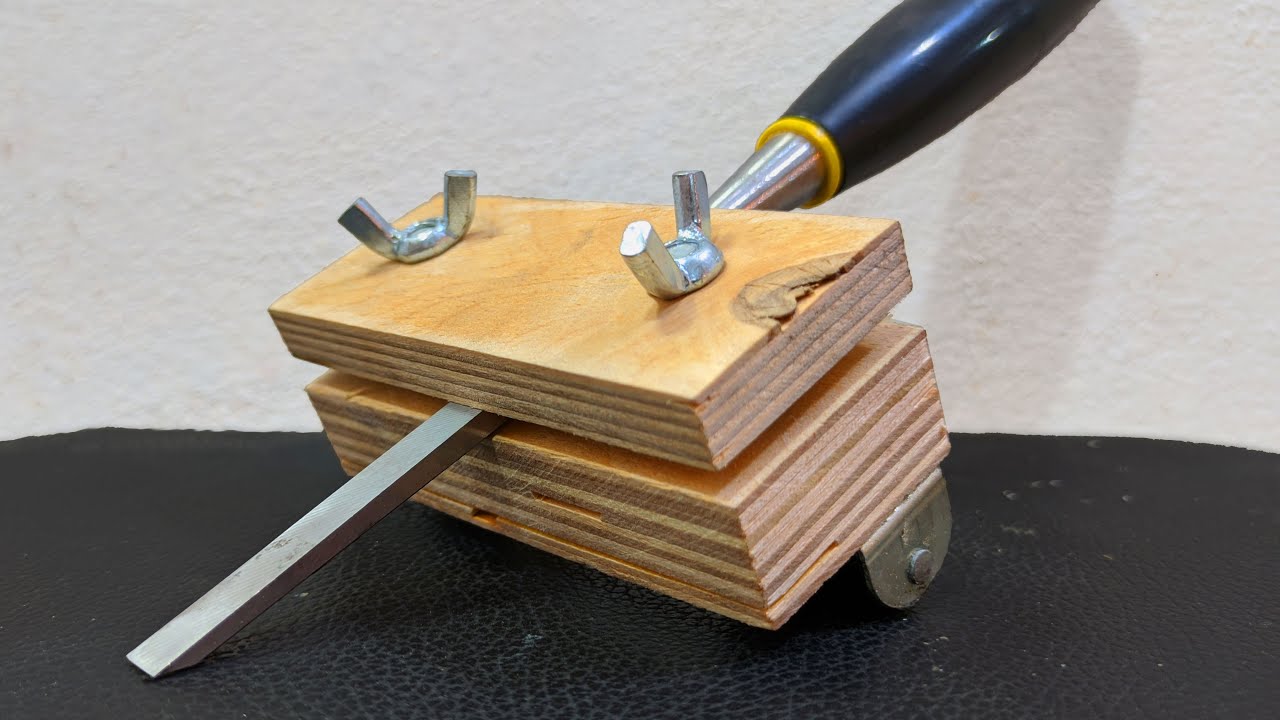

Making A Wood Turning Chisel Sharpening Jig

Now Ill change the grinding wheel sandpaper.

Making a wood turning chisel sharpening jig. Same as any craft woodturning demands a strong foundation in the basics knowing the wood properties tools techniques and most especially design techniques or considerations. After a bit of practice the sharpening becomes quick and easy. The long tubes should have 2 holes drilled in the top.

Honing Guide and Angle Tool Set Chisel Sharpening Jig Knife Sharpener Angle Tool Kit for All Knives and Wood Chisels 18 to 1-78 Hand Planer Blades. For the Varigrind I use two scraps of ply glued together in a wide flat V. Just ignore those bits in the middle.

By building a chisel sharpening jig or chisel sharpening station if you prefer you can get the process done much quicker. Its design will depend on the grinding jig. Grind the tip first and then pivot and swing the jig in each direction as shown to create an even grind.

See more ideas about lathe tools wood turning woodturning tools. Oneway Wolverine Vari-Grind Jig. Each is 25mm from the end of the tube.

This is a sharpening system that comes with everything you need to sharpen your turning tools. At Lathe Tools UK we have dedicated ourselves to making top quality sharpening jigs that are simple to use whilst giving you the uniform sharp bevel edge we all need time after. The scraper is one of the easiest tools to sharpen the only technical part is the angle most literature suggests using a 70 degree angle.

Identify two reference points on the jig and make a template to position those points. Now to use the jig all you do is slide your blade or chisel into the slot tighten slightly until you have it adjusted up to the stopper and also have the side of the chisel or blade aligned with the side of the alignment tool then finger tighten and you are now ready to sharpen that tool. I drilled the holes the next size or 2 up from 516 so the screws had some room and the there is some room for error in welding the nuts.