Types Of Holding Tools In Workshop

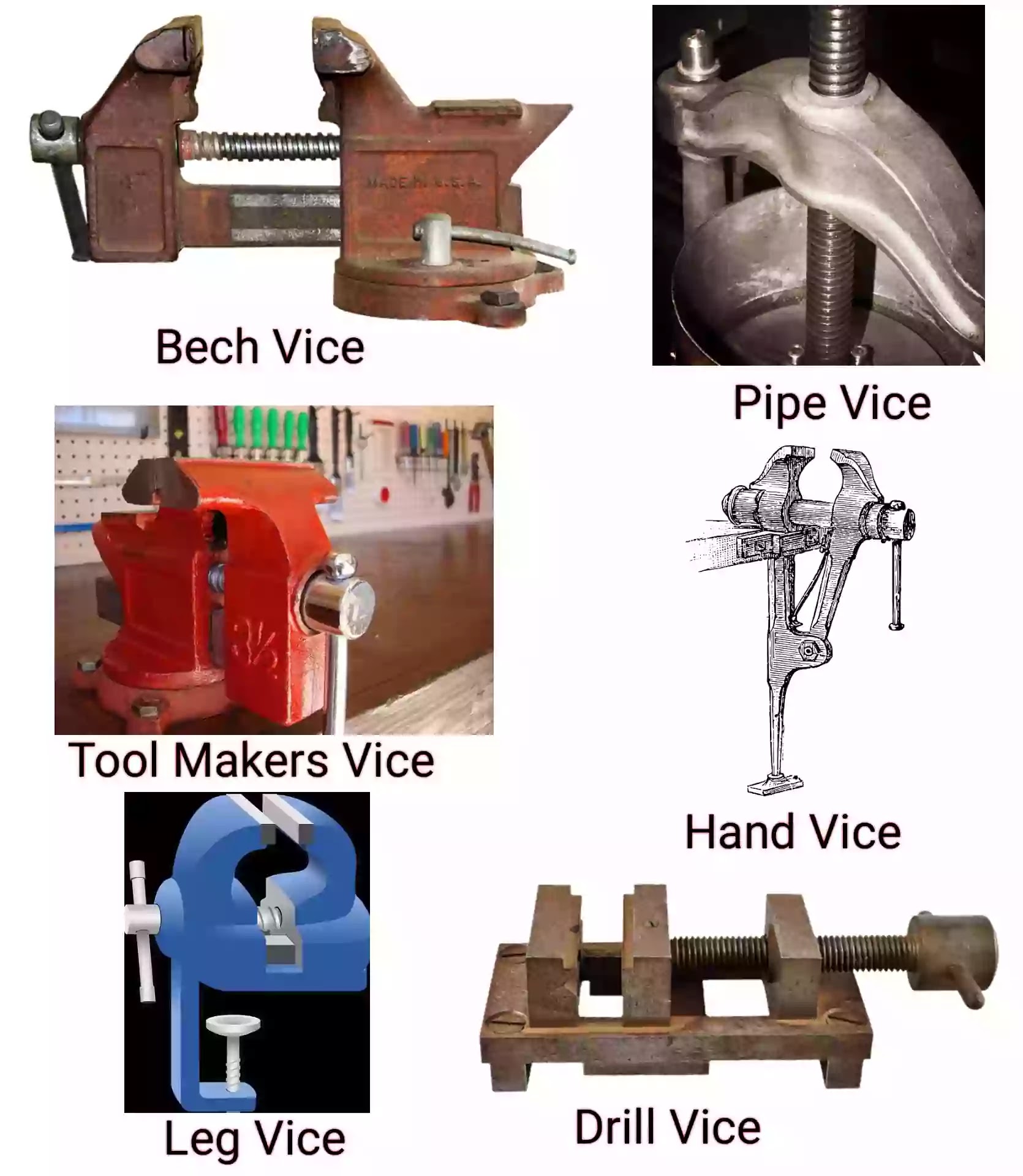

They are used to hold all types of components between jaws Fixed Jaw and Movable Jaw.

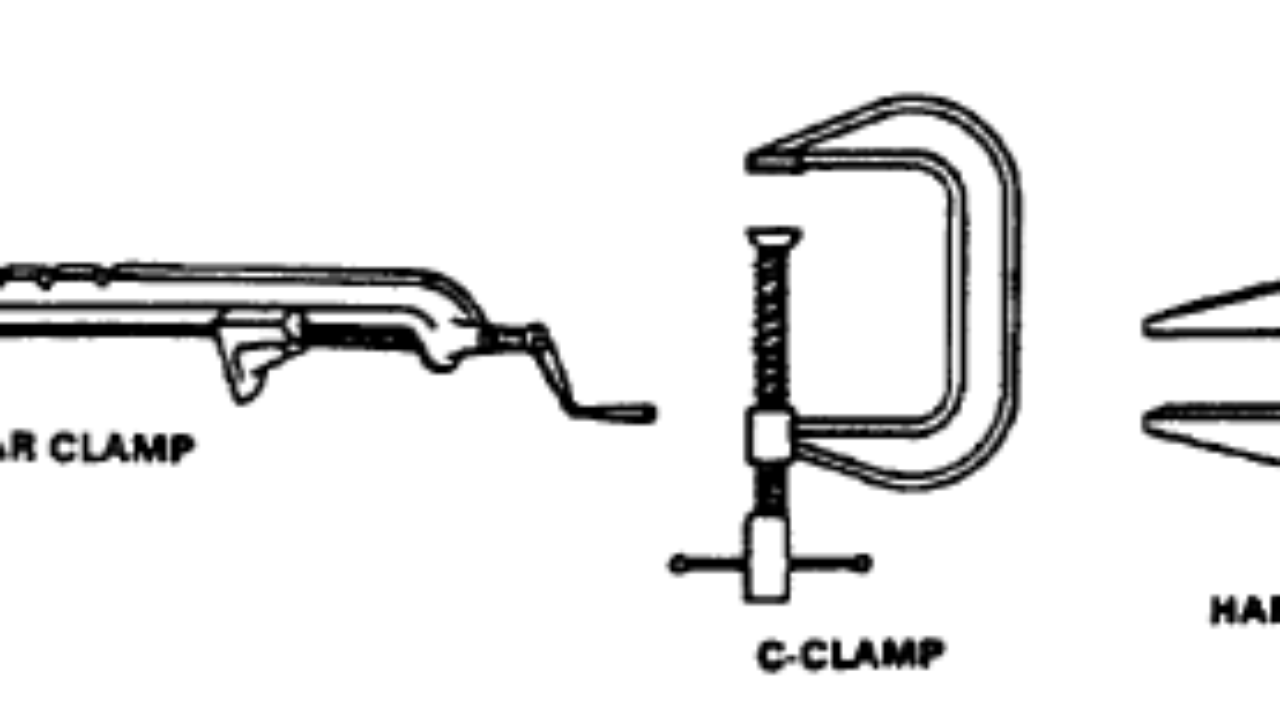

Types of holding tools in workshop. Copied from Basic of Manufacturing Processes and Workshop Technology by Rajender Singh. Holding Tools used in Engineering Workshop. Hand Vice 5.

One of the most commonly used work-holding devices is also called a drill press vise. Take a look at the hydraulic wedge spreaders we have on offer by clicking the button above. The vises provide the quickest and most efficient set up method for parallel work.

The body of the vice is made of cast- iron. For holding circular workpiece for marking out or machining. Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting.

Drill vise is a holding device used for clamping most workpieces while drilling. Holding tools are also known as Work Holding devices in the Fitting workshop. The specimens were taken and that you will see in the engineering workshop.

They are fixed in a die stock for holding and adjusting the die gap. Dies are the cutting tools used for making external thread. Friction-free unlike hammers and lever bars these hydraulic wedges limit any damage to the joints.

This type of workshop is more than long enough for participants to get bored or overwhelmed. Dies are made either solid or split type. Common concepts in schools with Holding tools.