How To Sharpen Carbide Metal Lathe Tools

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup.

How to sharpen carbide metal lathe tools. Everyone knows that the hardness of cemented carbide is very high. I talk about some techniques I u. How to use a slow speed grinder to sharpen carbide tooling.

Carbide tools can be sharpened on an ordinary bench grinder but it does not do the best job in terms of finish. It will grab and possibly rip the stock from the chuck or damage the lathe itself. How to sharpen lathe cutting tool first of all we must choose the right grinding wheel.

Carbide does not lend itself well to offhand grinding although it can be ground that way. It is a sled which rides atop the SVD-110 Tool. So in short you can sharpen carbide lathe tools but it takes a little more effort and it wont make them quite as sharp as fresh inserts.

Ad China Metal Lathe. Positive rake will make your tools free cutting reducing deflection and power requirements. At present the commonly used grinding wheels are alumina and silicon carbide.

When you sharpen a lathe tool bit youre really re-drawing a number of critical angles. With steel you can use 10-20 degrees but never try to use a tool ground for steel on brass. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner.

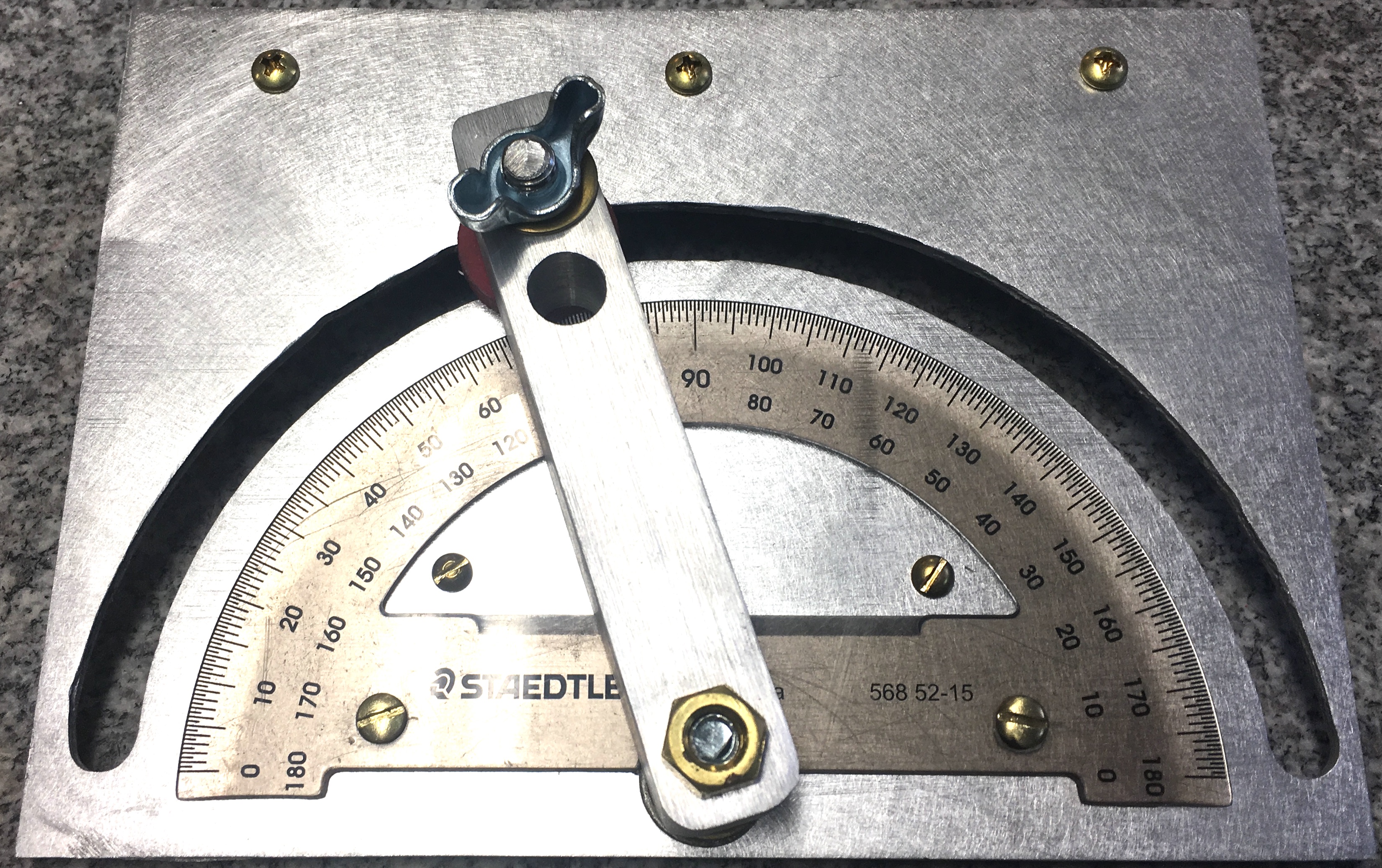

In particular the angles must be precise for best cutting action. Ad China Metal Lathe. But considering the cost of carbide tools it makes sense to get the most use out of.