How To Sharpen A Metal Lathe Parting Tool

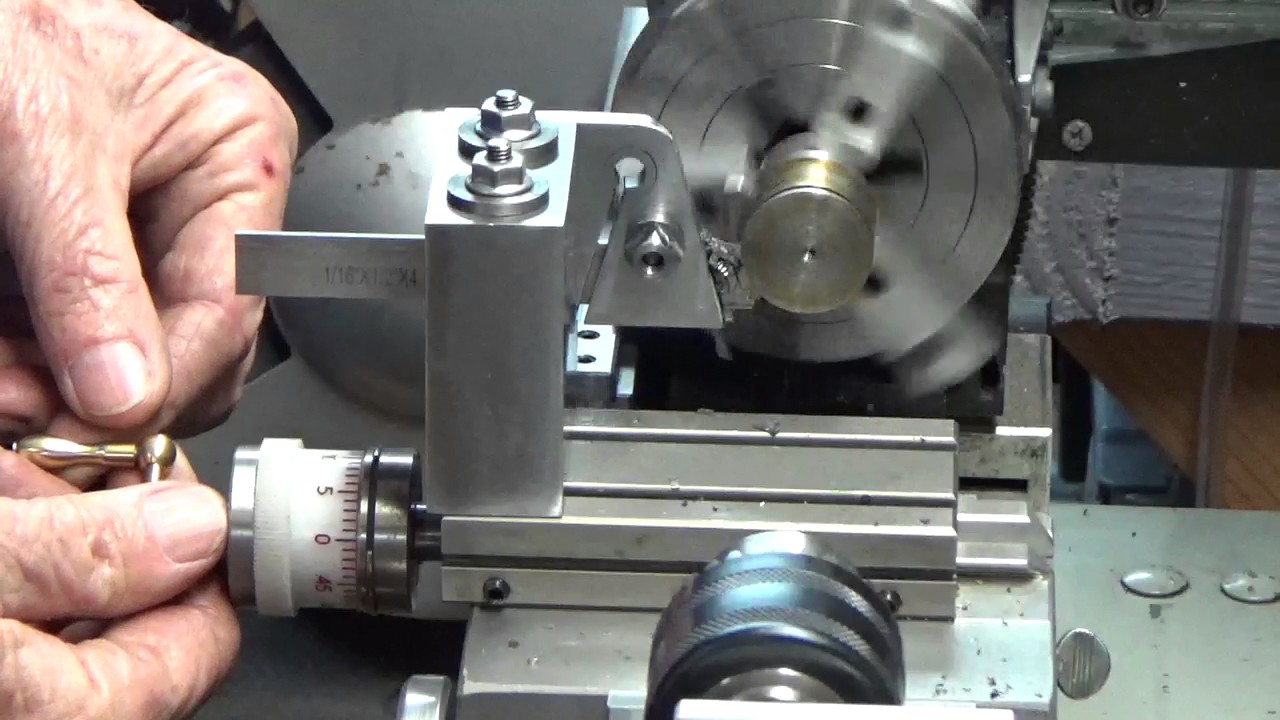

Shown below is what Ive put together to achieve the level of accuracy desired.

How to sharpen a metal lathe parting tool. The grinding rest was tipped to give the required side clearance relief and the fence adjusted to give the side cutting edge angle. Video on how to properly sharpen and use HSS parting blades. In profile this looks just like a worn tool.

Grinding angles start on next page ROUGHING GOUGE. The un-skewed cutting edge of the parting tools actually makes them much easer to sharpen. Trusted China Suppliers Verified by SGS.

Need to buy a new cutter now. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. In general the method is to use either a grinder or belt sander and then finish with a hone.

Even though the overall relief angle might be 8 its the almost microscopic angle at. If using an indexable part-off tool check that the cutting insert is in good condition. In this example we are making a normal right handed tool for the lathe.

Shaping skew chisels are pretty easy to do as well. I shattered my parting tool while making a 3 inch cut. In particular the angles must be precise for best cutting action.

Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds. Begin by dressing the grinding wheel. Next look up the typical angles for the workpiece material and then follow the steps in Figure A2.