How To Setup A Parting Tool On A Lathe

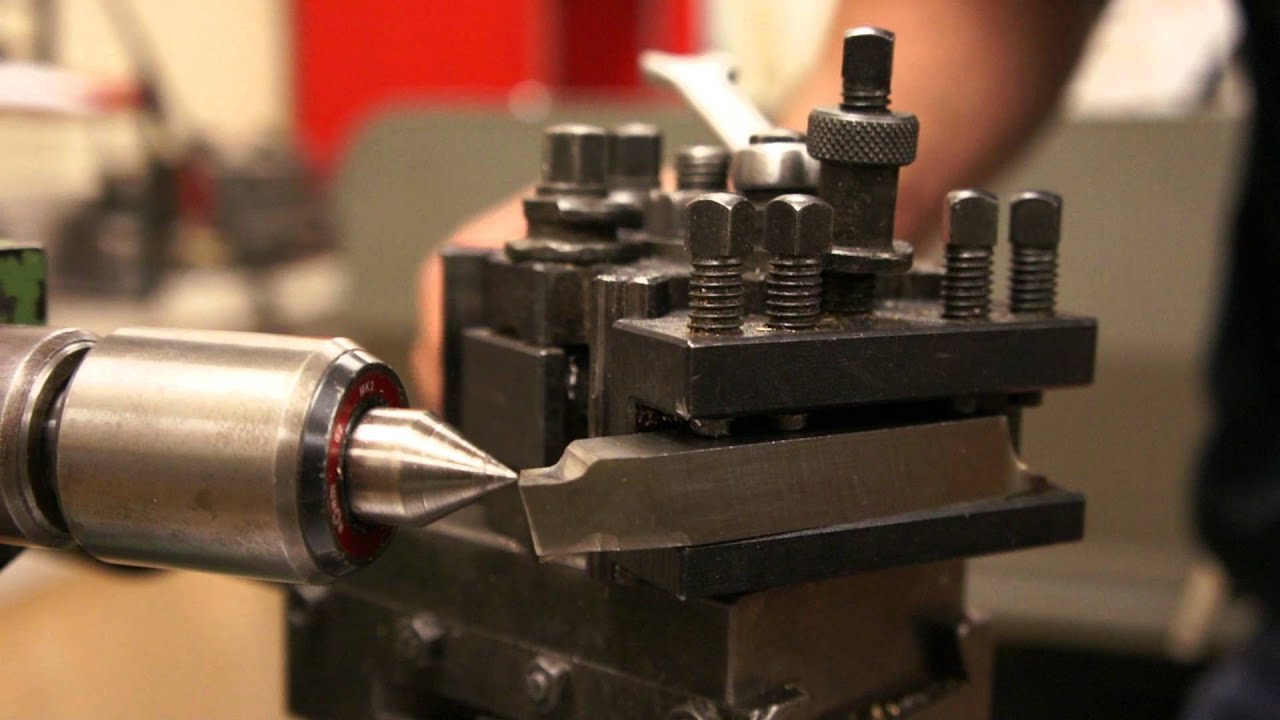

The blade holder and a bar I milled and drilled and tapped 14-20 to bolt to the blade holder that holds the whole assembly in the tool holder.

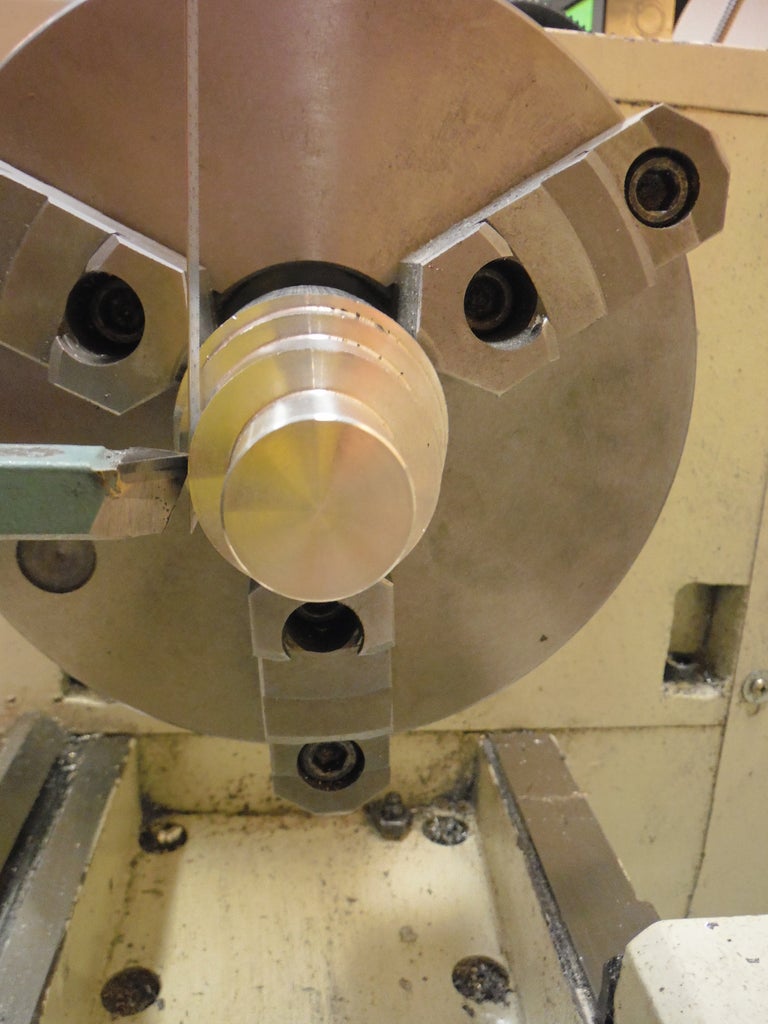

How to setup a parting tool on a lathe. Parting off bowls and lids When turning a bowl on the lathe and holding it by a tenon in a multi-jawed chuck the parting tool can be used to part the bowl from the lathe. Mount a cutting tool onto the tool holder or tool post securely and set the holder perpendicular to the part. Hollow the interior of the bowl and finish both sides of the bowl.

Parting tools of almost any sort seldom give the best possible finish. Not a very good shot but it does show the thickness. I then cut the end of the blade off to square it off and I cut and ground down the teeth.

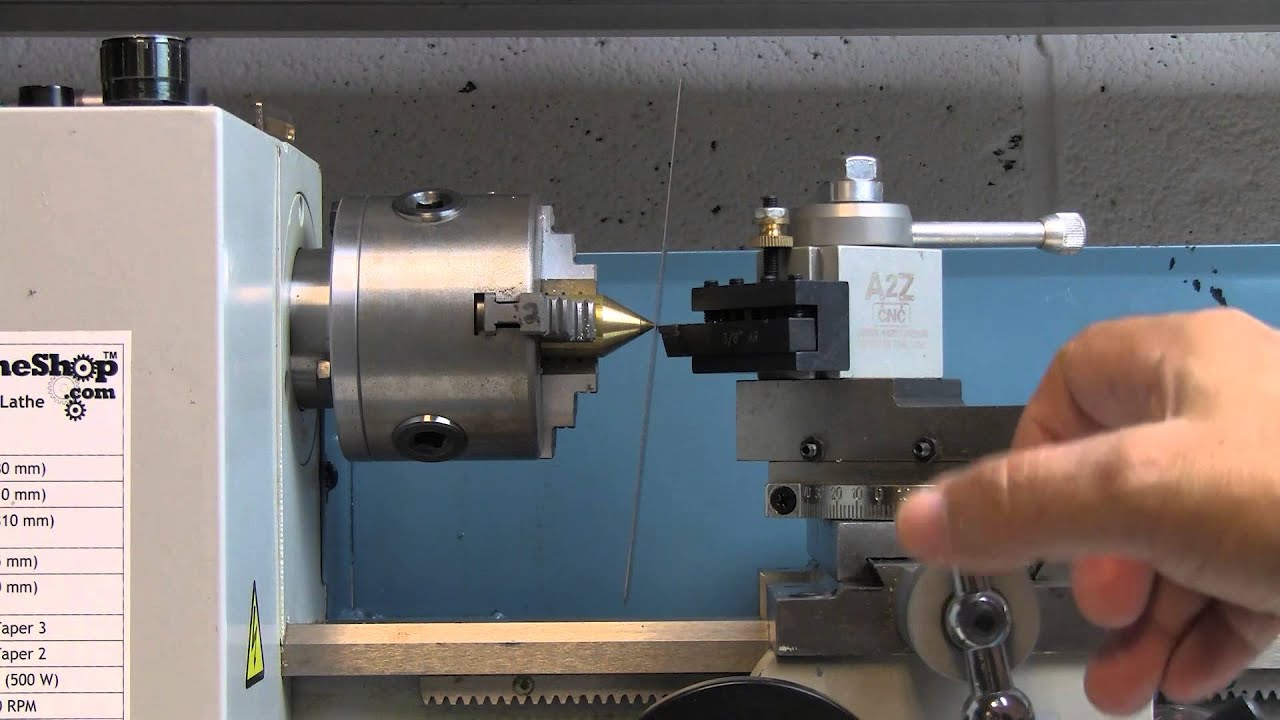

45 is a good general angle. Like all tools used on the lathe the part-off tool height must be checked and adjusted so it is as close to the vertical spindle centerline as possible. Often enough to avoid having to face it off in a second op.

1 x Key insert remover. I shaped the end of the blade like the Sorby Parting Tool double angle look. Double Angle Sorby Thin Parting Tool.

2 x 22mm Parting inserts. 1 x 26 x 2mm Parting blade. Keep advancing the tool until you get a steady chip curling off the workpiece and then try to maintain this cutting speed.

Lots of good hss parting blades--I use Empire but others are fine 5. When machining with long overhangs it is especially important to mount the bar correctly to ensure enough clamping contact. Second if the tip of the parting tool is ground at an angle it will minimize the nib further.