How To Make Your Own Cnc Wood Router

There are 3 steps to the project Construction Software Manufacture.

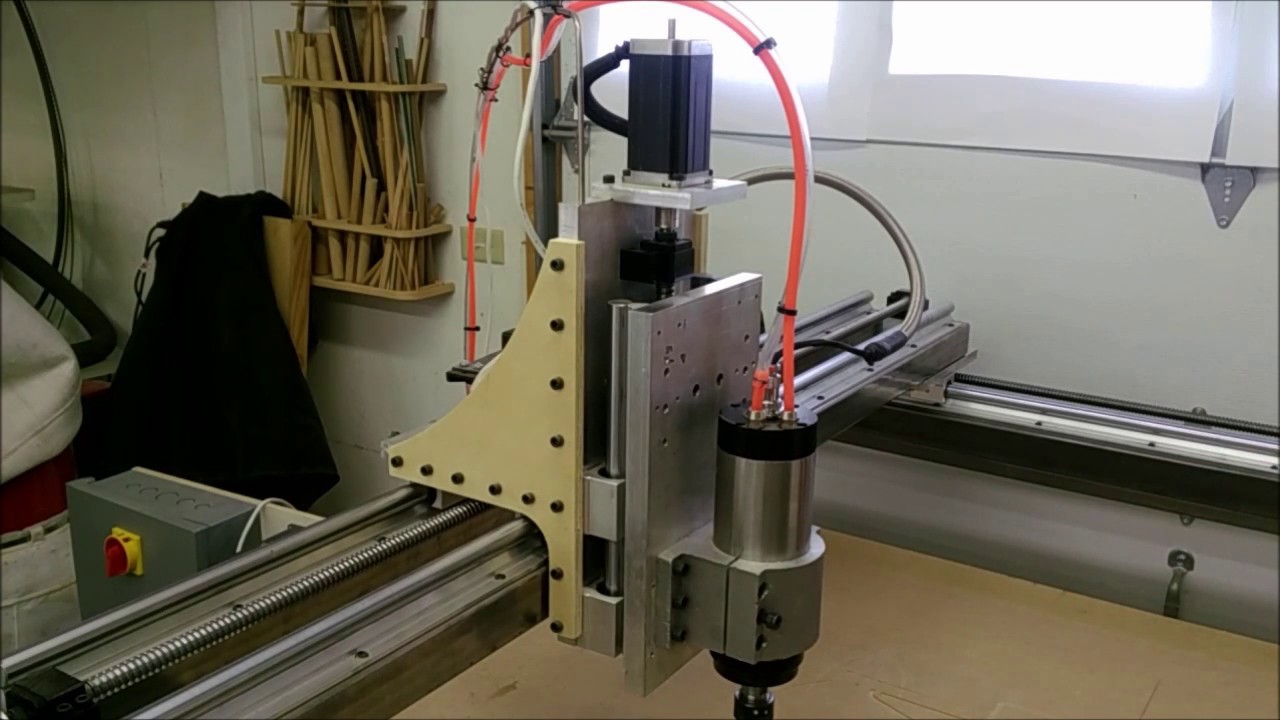

How to make your own cnc wood router. This is how I built myself a CNC router from wood that can even machine metals Support me Patreon. This is the second DIY CNC Router I made after learning a lot from building the first version. This design can be amended and would suit machines from 2400mm x 1200 down to 1200 x 900mm.

3 425 oz-in stepping motors 3 Drivers 30Amp 24-40 Volts 1-164 micro-stepping 1 36v 88a Power Supply 1 Breakout board I wired all the electronics up and added a few more features. But a few students made some simple modifications and improvements. Drill and tap some mounting holes in the edge of each bearing and.

Before assembling your machine ensure you have these tools. A set of metric and imperial hex keys 316 and 5. These plans document all the steps I followed to make my DIY CNC Router.

Timing belts rack and pinion and drive screws. One of the first tweaks to the design was the drag chain shown above that keeps the wires organized and out of the way. If you are building a 3 axis CNC router you should buy a kit consisting of three sets of linear rails and two linear bearings per rail.

Musical instruments have high requirement on precision and aesthetics. CAD Design The first step in the process of cutting something with a CNC is creating a 3-dimensional object of the item you are wanting to cut. And yes you will need to treat all the measurement tools you use with utmost care.

I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. With 20 inches wide the kinetic sculpture can run several hours by a single winding. Kinetic sculpture - This amazing CNC sculpture will make it look good on your wall.