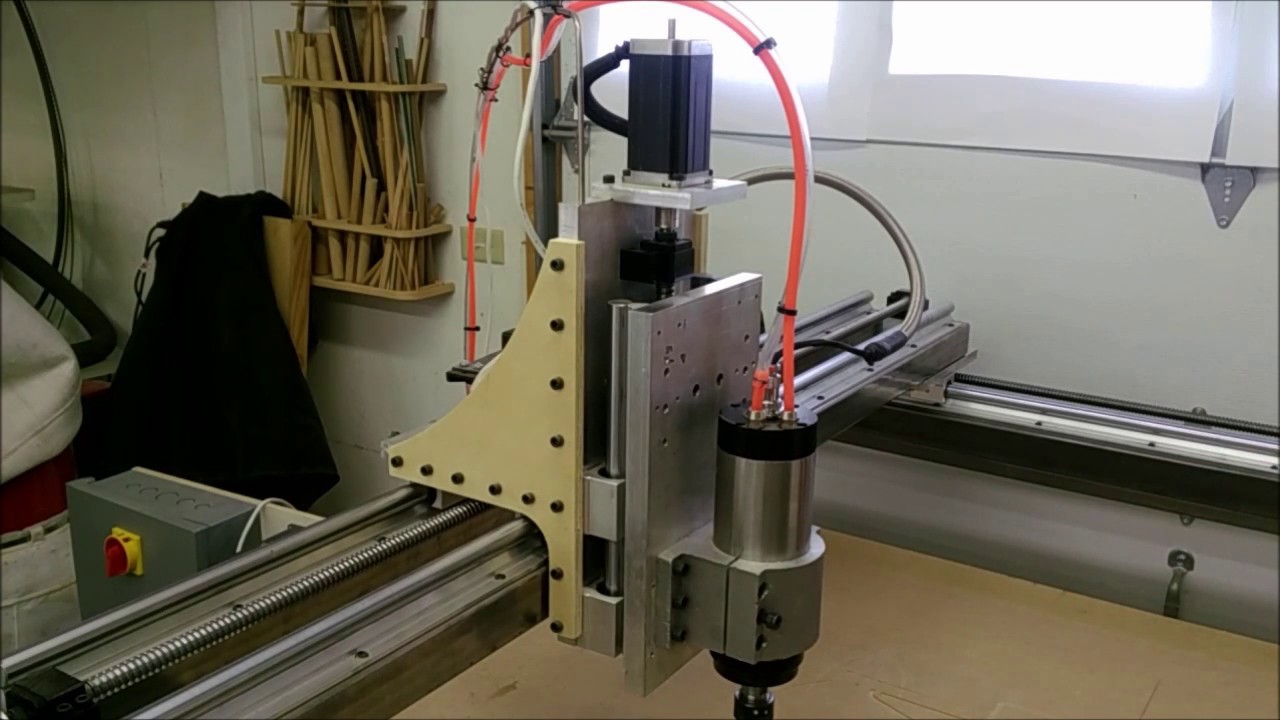

How To Make Cnc Wood Carving Machine

After long hours of research out how a CNC wood carving machine directly from the manufacturer functions was finally figured out.

How to make cnc wood carving machine. CNC carving is an increasingly popular hobby and one beautiful material to use is wood. Designers artists and hobbyists like to use this machine for making frames intricate door carvings decorative panels cheese boards puzzles and even musical instruments. While making signs is not exactly exciting work when the machine goes about making the sign its not like you have to stand and watch it.

Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis. I had to drill larger holes in the steel tube tops for screwdriver access. Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis.

Place your substrate under the drill head and turn on the CNCs vacuum to secure it in place. Make sure that this bit is appropriate for the surface you are engraving on. One the CNC machine begins executing a command it begins removing material.

I used 1 by 2 inch steel tubing bolted on top of 3x1 inch 80-20 aluminum for the underlying frame. Start the CNC router and begin the program by pressing the Start or green button. The machine can make these signs all by itself so you can go about doing other things while the CNC machine starts making.

Be sure you will get the best out of more than 4000 used machines and tools. The simple truth is the CNC utilizes a pretty simple mechanism. Because of how this CNC wood carving machine takes woodworking to another level a lot of investigations were carried out.

Best Machines in 2021. If you were to select a more basic machine it would be capable of making signs and relief pictures on wood. Make at least enough to pay for the machine.