How To Make A Parting Tool Holder

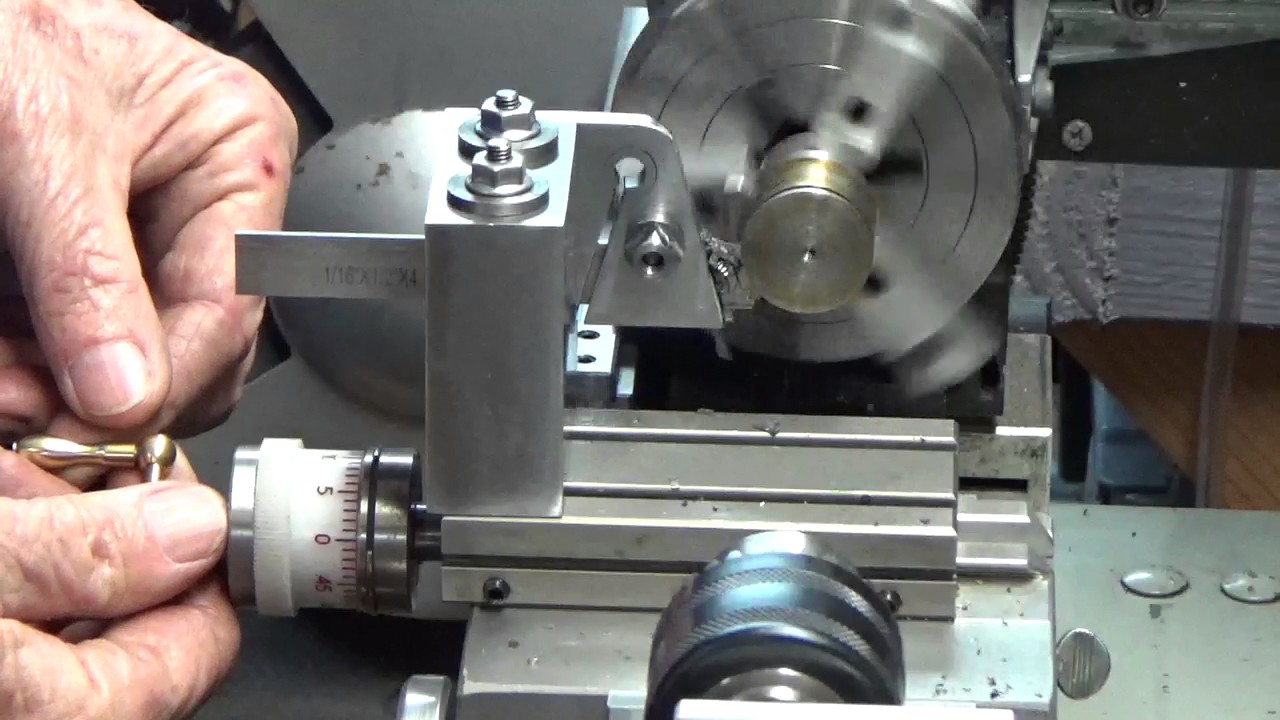

I had a short production run I needed to finish and part of the process required a small groove at the end of the piece.

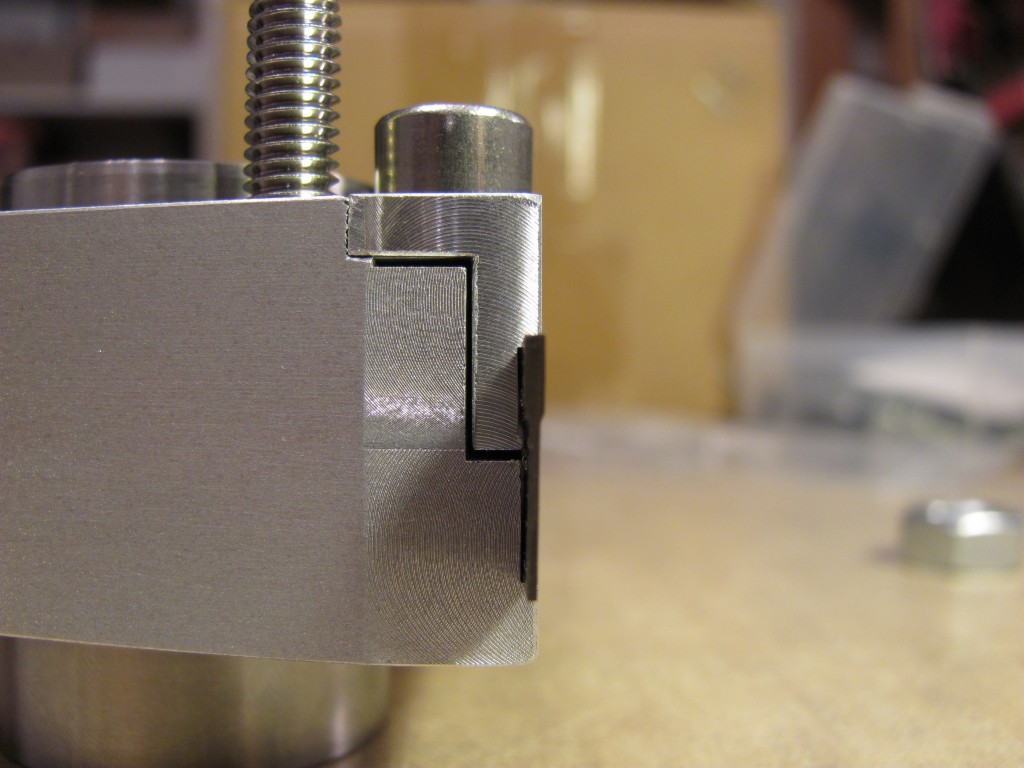

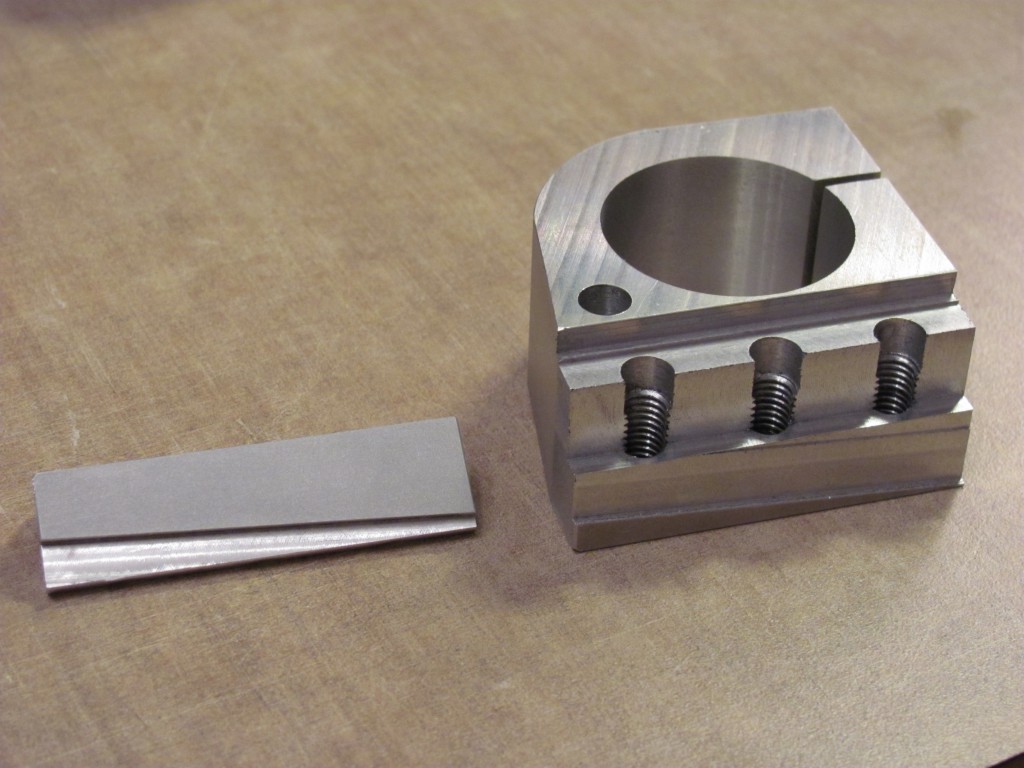

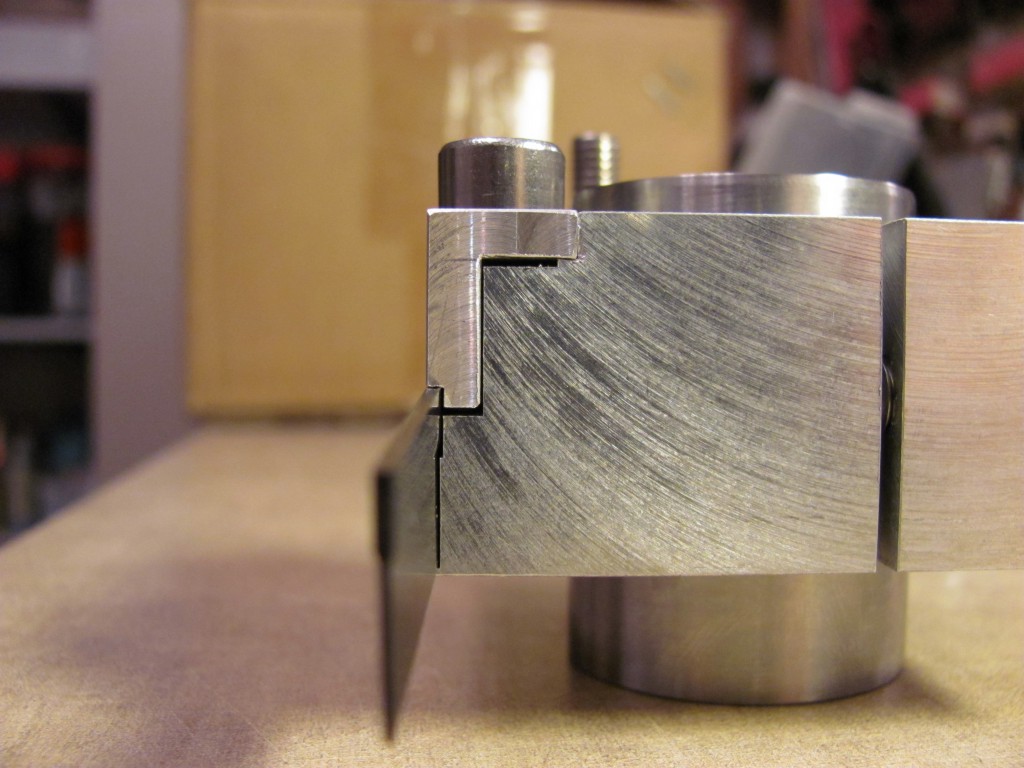

How to make a parting tool holder. A fits in another ie. Say 200-300 RPM or even slower. B a totally new holder that fits the tool post.

I find that locking my carriage is an essential step to take in order to maximize rigidity. The problem of snatching with HSS parting blades. Not sure of type.

For best process security use a tool with precision coolant. Fig cranked parting tool holder. The only way this happens is when the lathe is fitted with an American style toolpost.

Now lock the half nut in the engaged position to keep the carriage from moving during the parting cut. I needed a parting tool that would give a little so I based my design on designs I found on the internet. If superior tool edge sharpness is not necessary choose a 3-edge or 2-edge insert for a more economical solution or for larger diameters.

Its made from scrap. Repeat for 2 of the other sides. All parting has to be done with the cutter at right angles to the workpiece.

So I thought I would make my own parting tool for woodturning. This is two parts. Ive made a couple of turning tools with carbide cutters and some with HSS cutting blanks all turned out to be very useful.