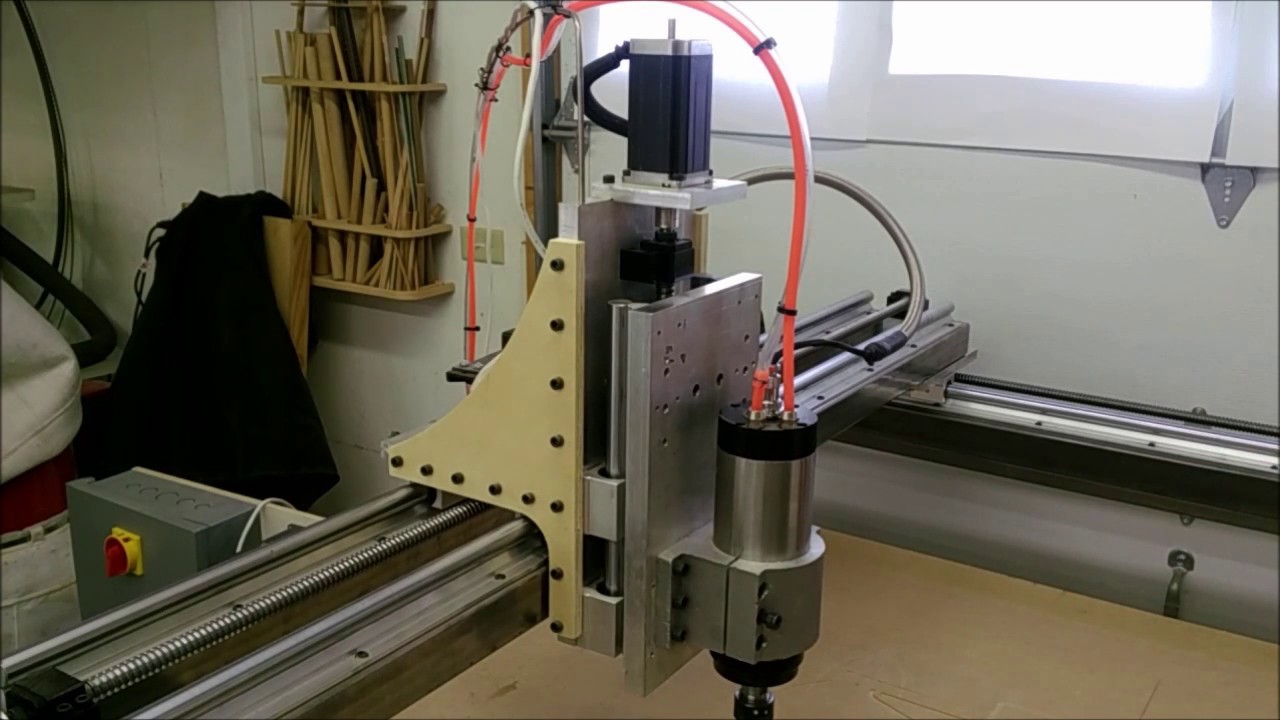

How To Build Your Own Cnc Wood Router

And its a lot of bang for your buck.

How to build your own cnc wood router. To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft. This project is ideal for tech-savvy woodworkers looking to add a CNC router. Nevertheless the key steps to build your own CNC machine will generally be as follows.

Build your own CNC explains how to build program and manufacture your own products on your own machine. He also made a few sweet upgrades. A compact router baltic birch plywood some basic hardware and an off-the-shelf electronics kit are all you need to build your own computer-controlled router.

This is how I built myself a CNC router from wood that can even machine metals Support me Patreon. A CNC machine is probably the most useful tool a hobbyist can own but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend. This is a very good router that can be built at a reasonable price using readily available materials.

It would be just like a professional is next to you guiding you every step of the way. 3x 8-32 x 1 ¼ machine screw. CNC wood router can make many instruments like piano guitar violin and others.

Assembled Option includes the complete CNC Router andor Laser is. There are 3 steps to the project Construction Software Manufacture. All you need to do is assembl the machine or find someone in your area that can assemble the machine We are building a list of individuals to help assemble in your area.

With a working area of 24x48 you can build this for a lot less than the cost of a similar commercial CNC router. A chop saw wood lathe drill and a drill press and finally a table saw nothing fancy but now with the CNC router he has a world of possibilities for projects. I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily.