How To Build A Successful Woodworking Business

There is just NO OTHER WAY to do it.

How to build a successful woodworking business. An exterior wood sealer is another essential product that is of great use when designing wooden products. For first-time business owners it makes more sense to buy an existing woodworking business than to attempt to build one from the ground up. Offering one of your products from your wood shop up for auction is a great low-cost your time and materials way to advertise.

You are not a giant mass manufacturer who can make and sell everything from tables to beds. These expenses are usually equal to 15 percent of materials and labor. Established woodworking businesses are already equipped with the resources and processes new business owners struggle to acquire.

Elizabeth Floyd has a good start on her own woodworking business. Well to make your own birdhouse you can use some very affordable and uncomplicated materials even leftover scraps from other projects and then sell it for a nice little profit. Overhead typically includes rent utilities and purchasing small supplies eg.

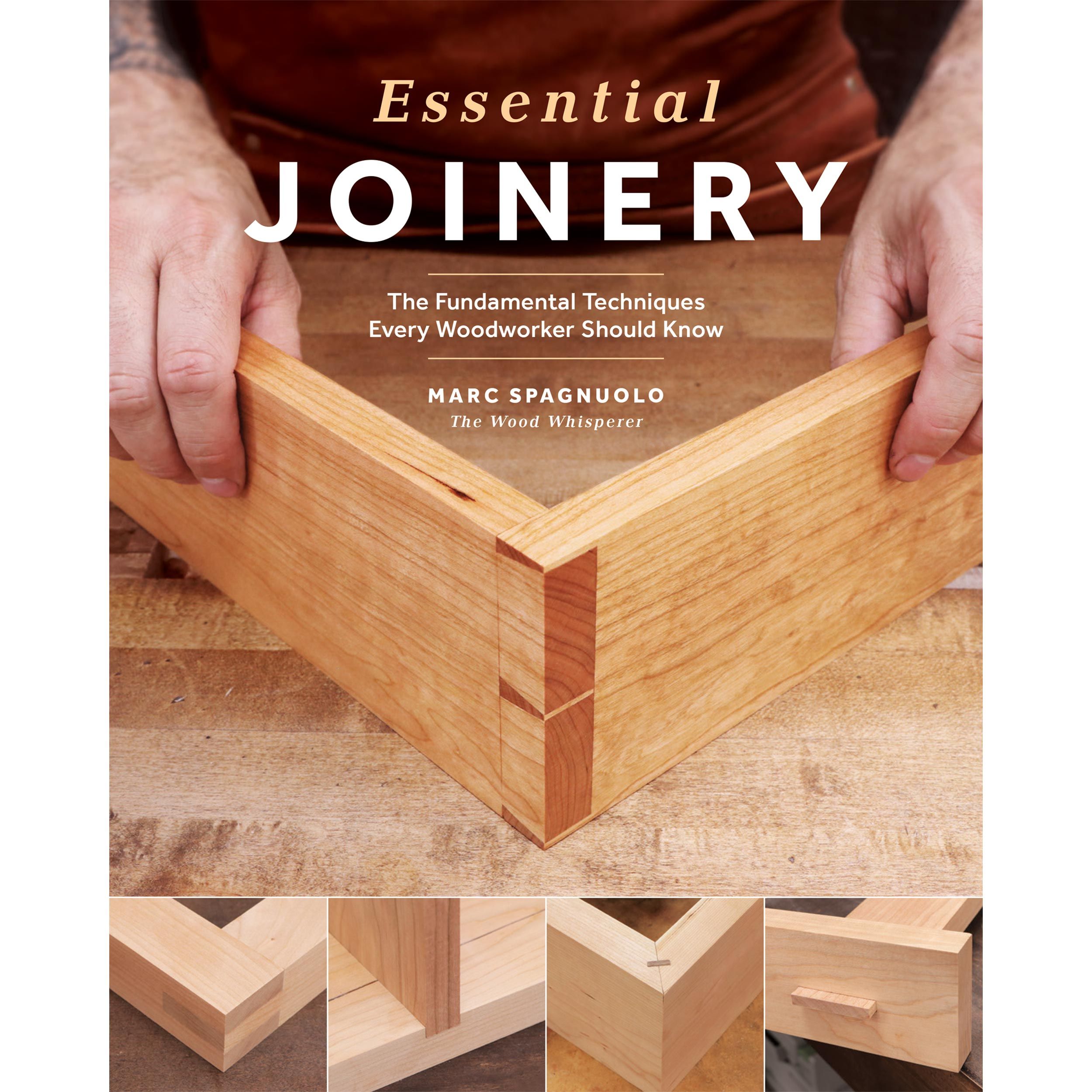

Hell you could start woodworking today and still be able to build a profitable business as long as you follow a few simple rules. Material costs should be covered by the sale of finished products. It will take more skill than mastering a mortise and tenon joint or hand rubbing a tabletop to a mirror-like finish to make your business a winner.

The business has been profitable for almost every month since starting thanks to low costs. The key is to locate a business-for-sale that closely matches your ownership philosophy and professional objectives. HOW TO BUILD A SUCCESSFUL WOODWORKING BUSINESS.

The rules themselves arent anything ground breaking but they make the difference between a successful side hustle or your main source of. We spoke recently with Woodmaster owner Elizabeth Floyd of Shelbyville Indiana. Nails sandpaper and finishing materials.