How To Build A Homemade Table Saw

The table saw fence is mainly used for ripping or.

How to build a homemade table saw. Maximum width of material for cutting at 45 degree is 11. You get three instruction methods in one so you dont have any excuse for not building your table saw stand. For really wide material screw or clamp a straightedge to the door.

In other words make sure that its sturdy and feels like it can stand up to the intended work. The table is marked for precise 225 45 and 90 degrees. But sometimes you need to make a new table saw fence when your old one doesnt work properly.

For this table saw stand you would need Mitre Saw some plywood lumber sanding discs screw leveling feet and some other items. Clamp the saw to the aluminum angle so its flush with both door bottoms. Plans for this projecthttpsibuilditcaplanswooden-table-saw-fenceThe build article for this project with the original build video and installation vid.

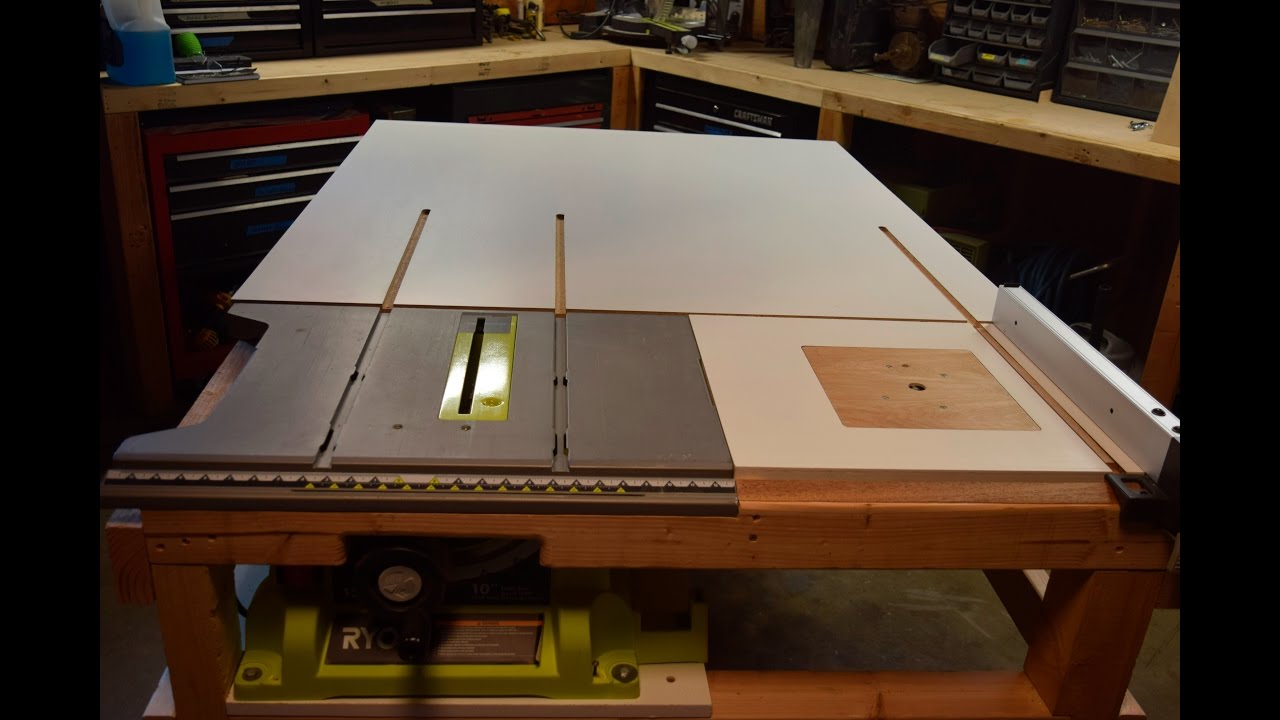

This time Ill make a homemade table saw by using regular circular saw How I did it - you can check by looking DIY video or you can follow up instructions bellow. Checking that the alignment is good with the saw blade parallel to the plywood. Melamine plywood or other board for table top and legs.

Checking how the pieces fit around the saw just held together by clamps. Screw aluminum angle to the edge of the opening placing its lip so the table saw surface will be even with the door tops. Very accurate cuts are easily made.

At beginning idea was to make a modular system but in process I changed. The table saw fence is an important part of a table saw. I also had to make sure I could still get the saw out without disassembling the bracket.