How Much Does It Cost To Start A Cnc Machine Shop

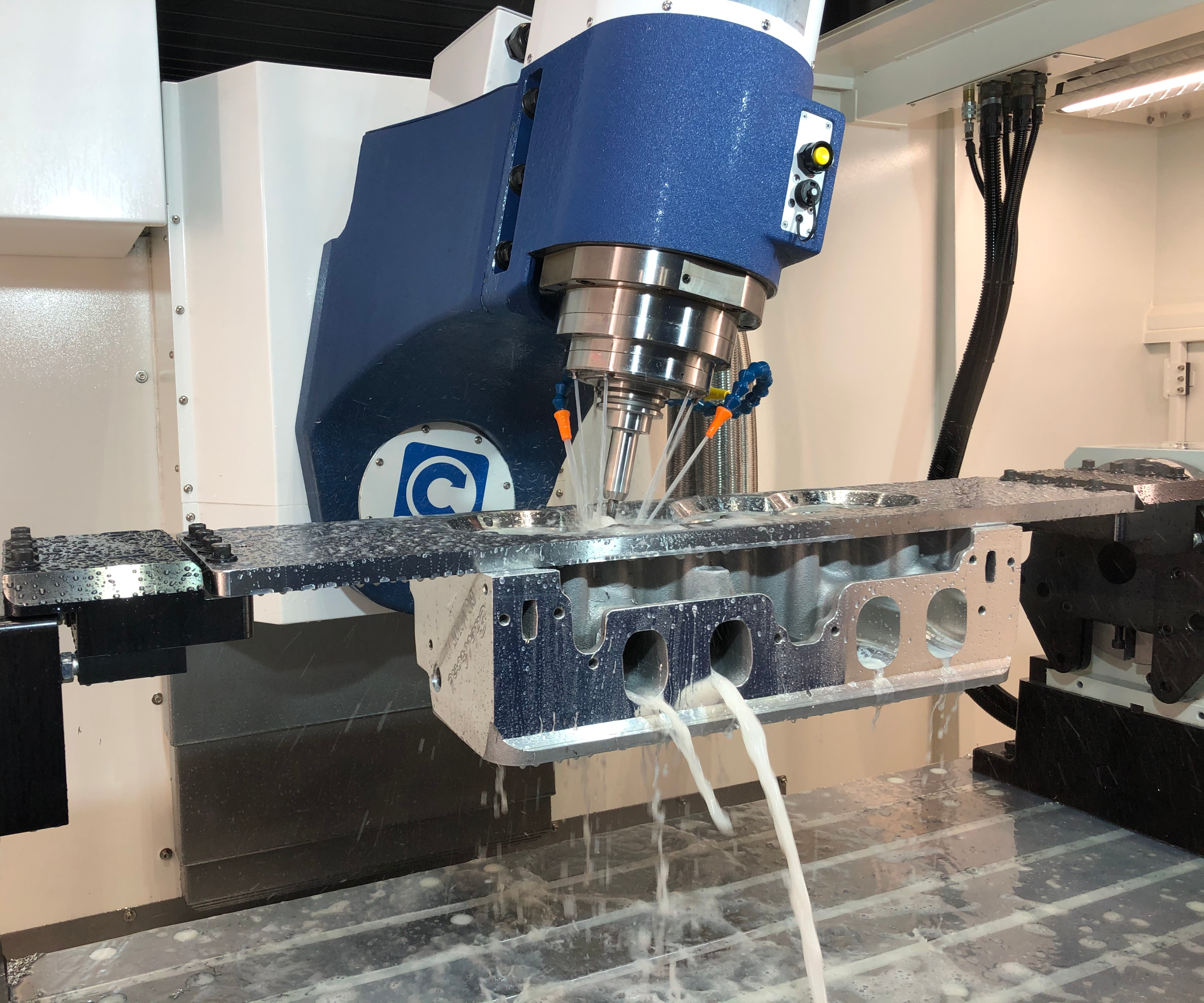

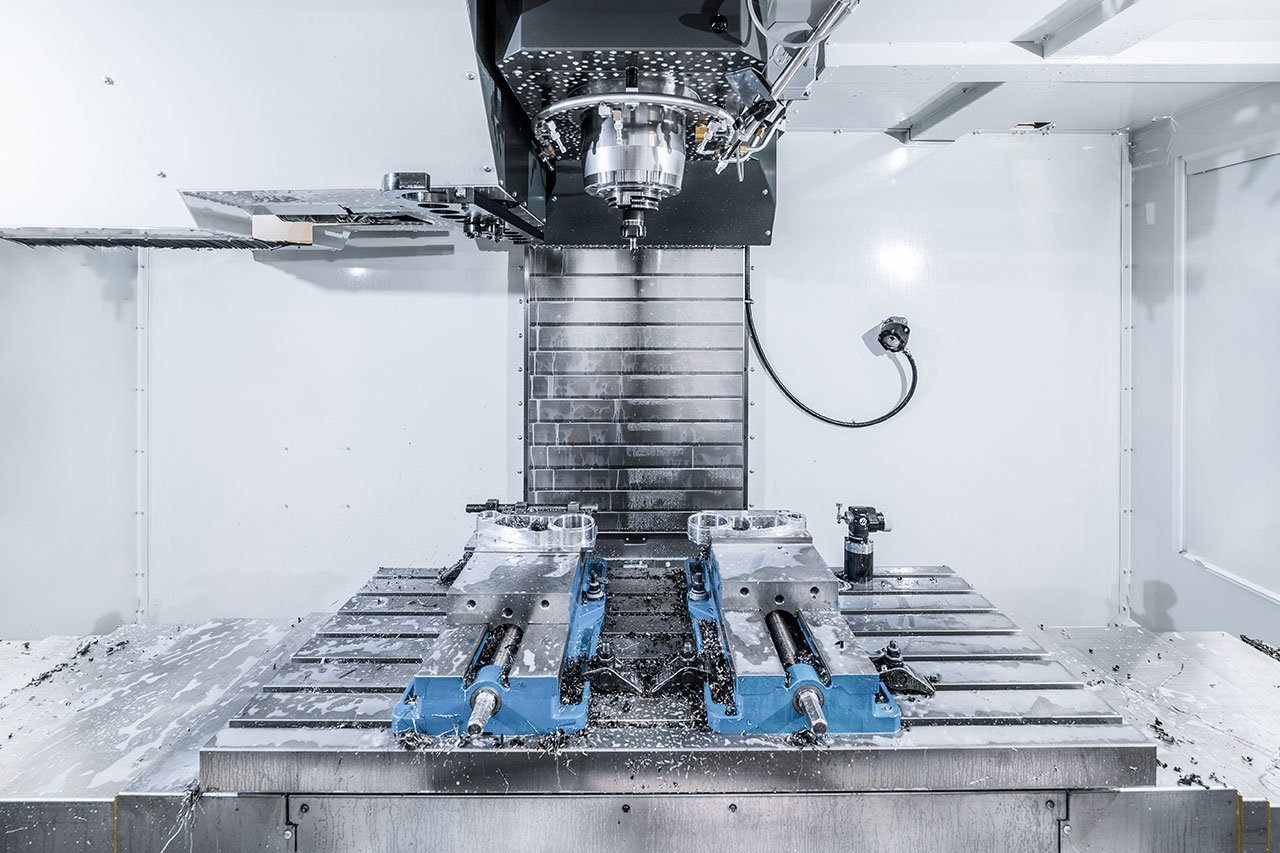

Scaling a CNC Precision Shop for Growth.

How much does it cost to start a cnc machine shop. You will need to understand the prevailing rate structure in your area to determine what you can charge for your products or services. Either buy your mill new or carefully test a. For another 8-10K and youd be on your way.

On the other hand there is a boatload of competition for the single-mill shop right now. These milling machines being mostly in the 3000-10000 range. From their toolroom mills and lathes to their small production machines you can expect to find entry level CNCs starting at about the 30k range.

If playback doesnt begin shortly try restarting your device. Simple calculation is markup 1 owners salary benefits annual earnings goal annual service hours machine labor overhead cost per hour. CNC machines arent inexpensive.

Haas is actually a really popular machine tool builder in the US that has a good lineup of entry-level machines. The study found that the characteristics of these higher performing CNC machine shops included gross sales that were 14 higher than other shops and median net income margin of 129 versus 59. Next to the field is a Calculate button that brings up this calculator.

Multi-axis machines are more expensive to run so will cost more. You can find the Machine Hourly Rate Calculator on the Machine Profile under the Setup Basics tab. Until you start looking into it you might not realize just how cost-effective and strategically savvy it can be to buy second-hand equipment rather than automatically opting for a brand new model.

Moreover the average growth rate for high performing CNC machine shops was 516 while the other shops averaged only 251 growth. Used CNC Machines Cost Much Less. The completed mailboxes can be sold on a wholesale basis to retailers or directly to consumers via a booth at a.